Driven by a Legacy of Engineering Excellence

At KPAC, we believe that the foundation of every successful product lies in thoughtful engineering and scientific precision. From concept to production, we apply proven principles and technical depth to ensure that every detail is optimized — not just for functionality, but for user experience, reliability, and manufacturability. With thousands of products to our credit and a team grounded in first-principles thinking, we transform complex ideas into solutions that are practical, cost-effective, and ready for the real world.

Engineering is not just our expertise — it is our passion.

Our engineers are passionate innovators, hands-on creators, and relentless problem-solvers.

Whether it’s experimenting with emerging technologies, developing intelligent automation

solutions, or designing complex systems from the ground up, we bring the spirit of

innovation to everything we do — both in our work and in our personal pursuits.

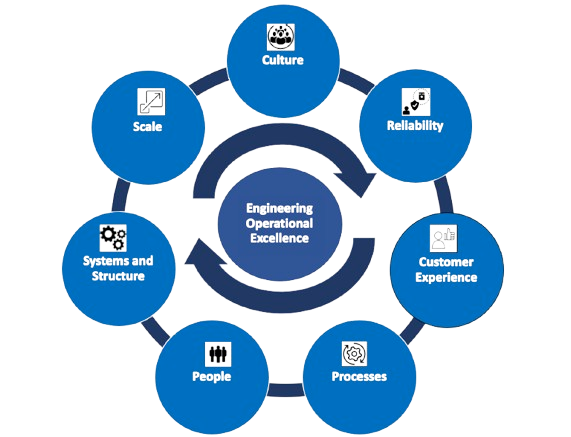

This deep-seated engineering ethos is at the core of every project we undertake at KPAC. As

your technology partner, we approach each challenge with a commitment to three key

principles:

- Functionality: Ensuring your product performs flawlessly in the real world.

- Feasibility: Engineering solutions that are ready for seamless manufacturing.

- Affordability: Delivering value-driven innovation without compromising on quality.

From concept to creation, KPAC is driven by a single goal — to craft engineering solutions that are reliable, scalable, and built for the future.

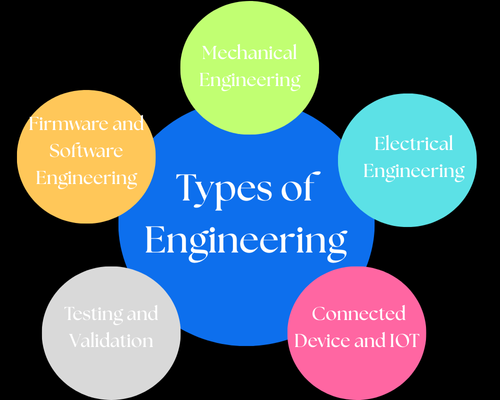

Engineering focused on your customers

Unlock the possibilities for your project with our team’s wide range of backgrounds and disciplines. We can solve virtually any design and performance challenge. Give us a call to talk shop and brainstorm engineering solutions for your project!

Let’s bring your project to life!

Our team of engineers is here to help. We offer free consultations and estimates.

Our Clients