Injection Molds:

We at MS Technologies focuses to achieve the desired precision and consistency in injection

moulds by careful selection of materials and features, making it a more sophisticated & thus

eliminating any risk of air bubbles, gaps, or other flaws in the finished product.

By eliminating the common risks associated with injection molding — such as air bubbles,

shrinkage, flash, and voids — we help our clients achieve flawless components that meet

tight tolerances and industry standards. Whether it's for automotive, consumer electronics,

medical devices, or industrial products, our injection molding solutions are tailored to

meet the specific demands of your application.

From prototype tooling to high-volume production molds, MS Technologies delivers injection

mold systems that stand up to the challenges of modern manufacturing — ensuring consistency,

efficiency, and superior product quality in every cycle.

Engineered for Your Needs

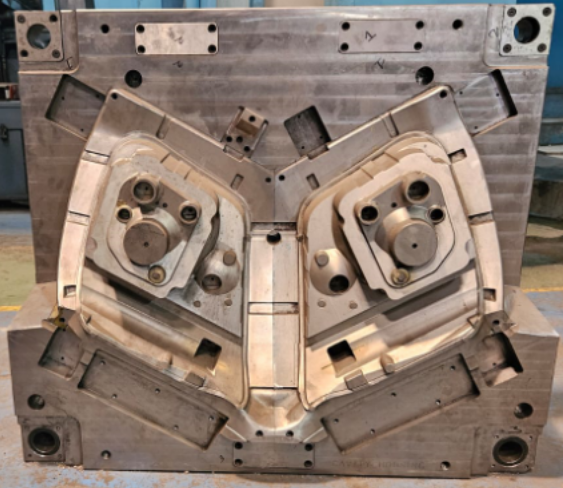

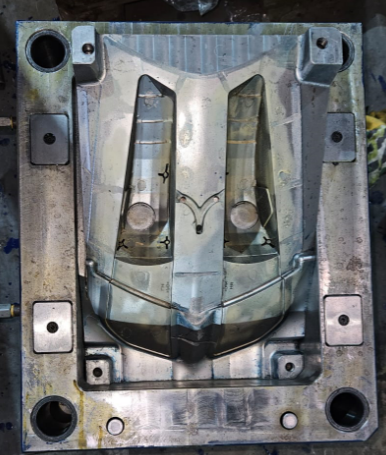

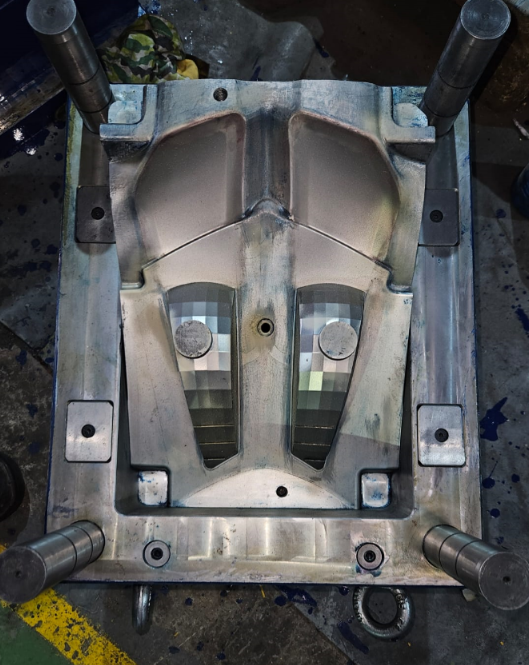

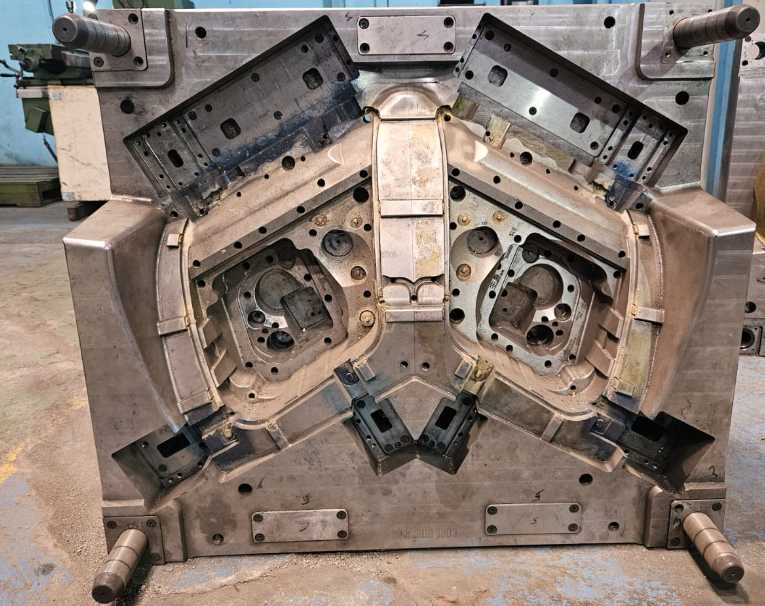

Injection Molds: Head Lamp Lens

We recently developed & successfully delivered a head lamp lens with critical under slider mechanism. The mold size was 1500X 1000X800.

Let’s bring your project to life!

Our team of engineers is here to help. We offer free consultations and estimates.

Our Clients